PRESS RELEASE: THE REVOLUTIONARY INTERMODAL WAREHOUSE SYSTEM™

EAST RIVERTON, N.J., -- Traditional transport procedures involve complex steps that slow the process, putting cargo and personnel at risk, while costing suppliers at every stage of the journey. As a solution to these challenges, SEA BOX, Inc., a leading manufacturer of shipping & storage containers, has introduced the Intermodal Warehouse System™ (IWS), which ensures the integrity of the transport process by providing a superior ISO container-ready solution that also doubles as a field warehousing structure.

SEA BOX IWS - IDEAL FOR EVERY STAGE OF THE JOURNEY

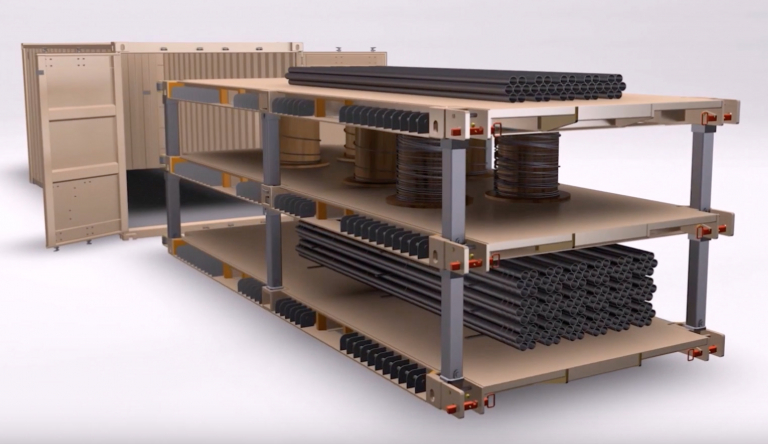

The SEA BOX IWS offers a unique design that provides superior performance at all points in the supply chain. At the shipping stage, the IWS slides and locks into standard ISO containers for the secure housing of goods. SEA BOX has also configured the IWS structures to be stackable via modular posts or simply flat atop one another. This design not only reduces storage space, it improves the inventory process and retrieval of goods. It's multiple stacking and sizing configurations maximize precious container real estate. Unlike many standard skid systems, the IWS also uniquely accommodates irregular and oversized payloads eliminating the need for costly open top containers and flatracks. This frees up the shipper to utilize the most commonly found and least expensive container in the world – the standard end opener. The IWS is the most versatile and cost efficient shipping solution on the market today.

PROVEN PERFORMANCE AND SAVINGS FOR MANY INDUSTRIES

While standard transport systems are intended to move freight from Point A to Point B, few if any can demonstrate significant cost savings throughout the supply chain.

SEA BOX has engineered the IWS for superior performance with the added benefit of real world cost savings for these customers.

Jim Brennan Jr., President of SEA BOX, states, "Recent customer reports conclude that our IWS delivers significant reductions in material handling time and labor requirements, equipment usage and storage space across a wide spectrum of segments including the military, oil & gas industry, commercial, industrial and exporting sectors."

In one instance it was determined that incorporating the IWS into the workflow reduced material handling times upwards of 80% in direct and indirect material and logistic (M&L) work hours. From material receiving, to yard maneuvering, to storage, the IWS reduced man-hours throughout the various stages of the process. In addition, heavy equipment costs incurred from cranes, tractors, and forklifts were reduced, and in many cases eliminated as the IWS can be maneuvered with a standard forklift.

THE IWS FACTS AND FIGURES

The IWS is manufactured to current ISO Standards and is available in 20 ft. and 40 ft. models. The entire structure is manufactured from high-grade steel and features

SEA BOX's unique inter-connectable design for stacking when loaded or empty. Each size feature front and rear forklift pockets, heavy-duty side rails and corner fittings, and vertical rollers for ease of use.

The 20 ft. IWS "210" variant features 22,046 lb. (10,000 kg) payload and 26,014 (11,800 kg) gross weight capacities. The 40 ft. IWS "425" variant features 55,115 lb. (25,000 kg) payload and 66,138 lb. (33,000 kg) gross weight capacities. Optional features are also available, which extend the use of the IWS for different applications.

When loaded, IWS can be stacked two or three high for transportation, effectively tripling shipping capacity. When unloaded, IWS can be stacked up to 10 high inside a 20 ft. ISO container or stacked up to 20-high for warehousing when not in use.

VISIT SEA BOX AT BREAKBULK AMERICAS 2018

Meet the SEA BOX team in booth #227 at Breakbulk Americas 2018 in Houston, Texas. SEA BOX will be featuring the Intermodal Warehouse System on the show floor.

ABOUT SEA BOX

SEA BOX, Inc. is an ISO 9001:2015 certified, U.S. small business established in 1983 by Jim Brennan Jr., specializing in the design, modification and manufacture of ISO shipping and storage containers, refrigerated containers, containerized shelters, modular building systems, and related parts and accessories for purchase or lease. The Company also offers a full line of parts, accessories and container enhancements such as cabinets, shelving and racks as well as specialty equipment such as generators, trailers and flat racks. With corporate offices and manufacturing facilities located in New Jersey, SEA BOX, Inc. also maintains an international presence with locations in Asia, South America, Australia and Europe.

For more information, visit https://www.seabox.com/products/list/intermodal-warehouse-system or contact:

Andrew Salerno, Head of Global Marketing

SEA BOX, Inc.

1 SEA BOX Drive

East Riverton, NJ 08077-2022

P: 856-303-1101

E: asalerno@seabox.com